Hi there,

So it depends on what method you are using But I believe your seeing the Task switch for the WiFi and or BLE portions to run, If it’s 2 cores then core one is dedicated to the Radio’s. S2 is a single core so the Rtos is blocking your PWM or motor control. You can research it more but I would bet that’s the issue. It takes a few posts for Spammer protection b4 you can posts links and pics in some cases. 3- 4 more reply’s will do it.

Have you tried an S3 or C6 probably have good luck with those.

Can you describe you program flow? and mechanically what you have connected? Stepper motor or Servo? any form of feedback?

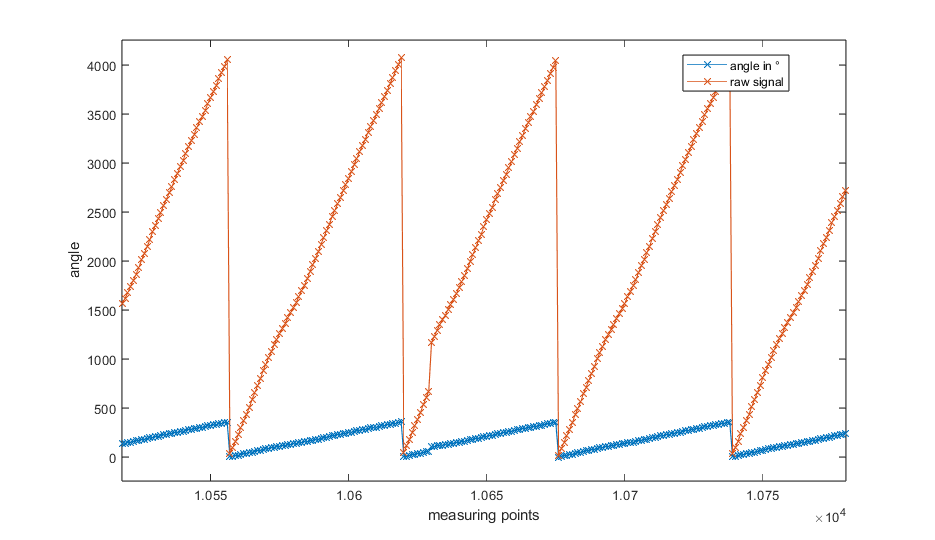

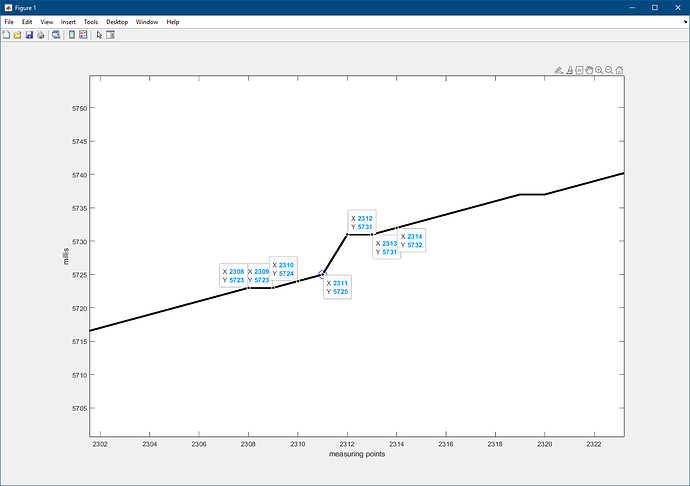

Encoder ?

Encoders (2 types) for example enable fine-tuned control of robotic arm movements, crucial for tasks like precise assembly or delicate manipulations.

I worked on a robotic Surgery device a while back, the movements and precision is possible only by feedback from the motors it’s key. The encoders on a robotic arm motor is a sensor that provides precise information about the motor’s position, speed, and direction of rotation, allowing the robot controller to accurately control the arm’s movement by making real-time adjustments based on this feedback data; essentially, it acts as a “closed-loop” system to ensure precise positioning and movement of the robotic arm

Now you may not need that level of precision but the principle applies the same.

HTH

GL:-) PJ

if you just mean a camera slider or something , then there’s tons of videos on those too! some really clever designs.

A few moments LATER…

So I recalled an automatic ability, and asked the AI and I got this which is exactly what I was trying to recall if possible.

You got to love this stuff " Hey Milton " previous discussion, end,

Answer;

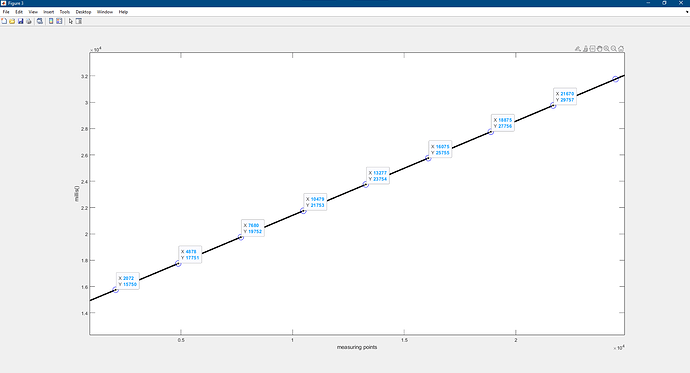

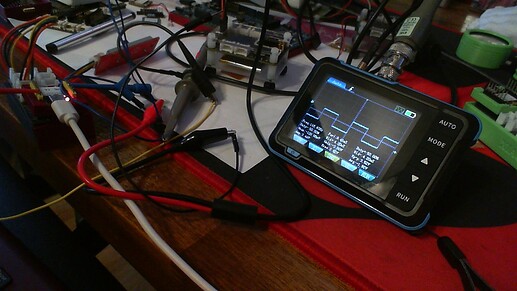

Your intuition is likely correct. On the ESP32‑S2, all tasks—including those for WiFi/BLE—are running on the single core. This means that when the RTOS switches tasks to handle WiFi or BLE operations, your time-critical ISR for generating the step/dir signals can be momentarily preempted, resulting in that roughly 5 ms gap every couple of seconds.

In contrast, dual‑core devices like the ESP32‑S3 or ESP32‑C6 let you dedicate one core (or schedule tasks more effectively) to the critical motor control routines, while the other core can handle the radio stack. This separation can greatly reduce those timing glitches.

Does that align with your observations?

Answer:

ME, "Yes, and I wondered or remembered something about using the peripheral features to allow it to run independent of cpu? "

WOW…

GET READY!

Boom!

Yes, that’s absolutely possible. The ESP32 family includes several peripherals that can generate precise pulse outputs without constant CPU intervention. This is ideal for applications where timing is critical, such as generating step/dir signals for a motorized microscope table.

Two Common Approaches

- Using LEDC (LED Controller):

- What It Is:

LEDC is a hardware PWM generator built into the ESP32 that can run completely independently of the CPU once configured.

- How It Helps:

By using LEDC to generate your step pulses, you offload the signal generation to hardware. This means that even if the CPU is busy with WiFi, BLE, or other tasks, the LEDC peripheral will continue generating a consistent PWM output.

- Usage:

You configure the frequency and duty cycle, and the LEDC module maintains that signal autonomously.

- Using RMT (Remote Control Module):

- What It Is:

RMT is a flexible peripheral designed to generate and receive precisely timed pulse sequences.

- How It Helps:

RMT can be programmed with a series of pulse durations and levels, and it will output these pulses without CPU intervention. This is particularly useful if your step signal pattern is non-uniform or if you need a complex pulse sequence.

- Usage:

You load a buffer with the pulse timings and levels, and the RMT peripheral handles the rest.

Why Use These Peripherals?

- Consistent Timing:

Since the signal is generated entirely in hardware, it’s not affected by task switching or interrupts caused by the CPU handling WiFi/BLE stacks.

- Lower Jitter:

With hardware PWM or RMT, the pulses are generated with precise timing, reducing jitter and ensuring smooth motor operation.

- CPU Offload:

Your main CPU is freed up to handle other tasks (like processing sensor data or managing communications) without compromising the timing of your motor control signals.

Implementation Considerations

- Frequency and Resolution:

Check that the chosen peripheral (LEDC or RMT) can operate at the frequency you need and that its resolution meets your requirements.

- Peripheral Resources:

On devices like the ESP32-S2 (single-core) or ESP32-S3/C6 (dual-core), using these dedicated peripherals is especially advantageous because they can run independently, even when the CPU is handling other critical tasks.

In Practice

here…

For example, if you need a steady step pulse at a high frequency, you might configure LEDC with a specific timer and channel, set the desired frequency (e.g., 2 kHz), and then simply start the PWM signal. The output will be maintained by the hardware until you disable it or change its settings. My favorite choice…

Alternatively, if you need variable pulse patterns (for instance, to implement acceleration or deceleration profiles), the RMT module might be more appropriate since you can predefine a sequence of pulses and have RMT output them exactly as scheduled. May be better for a table with know movement patterns

Summary

By using the ESP32’s dedicated peripherals like LEDC or RMT, you can generate step/dir signals that run independently of the CPU. This helps avoid timing gaps caused by the RTOS handling WiFi/BLE tasks on a single-core ESP32-S2, leading to smoother and more consistent motor control.

Does that align with what you were thinking, or do you need further details?

Thank you… Well there you Go!

HTH

Let us know.