Feedback from a robotics / 6-DOF arm / industrial automation user

Dear Santa,

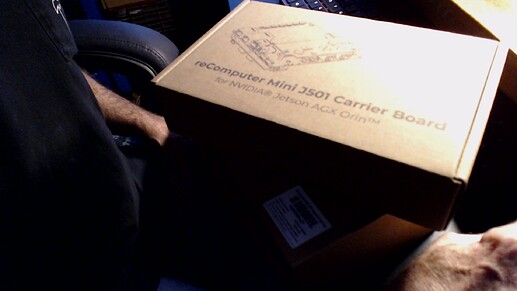

Seeed asked what users want from the upcoming Jetson AGX Orin carrier I want one to test., so here’s my take from the perspective of someone building 6-DOF robot arm systems using closed-loop NEMA17 motors with planetary gear reducers, machine vision, and real industrial fieldbus requirements.

Some parts are 3D printed and a few are CNC machined aluminum, with plans for some laser cut acrylics. Maker level accessible equipment and machines will be used.

I’ll keep it practical and focused on what actually moves the needle.

1. Industrial Motion Interfaces (Not Just “CAN”)

For robotics, AGVs, arms, and automation, these matter more than anything:

- 2× isolated CAN-FD channels (SocketCAN-compatible)

With galvanic isolation and screw terminals—no add-on hats needed. - 2× isolated RS-485 / RS-422

Useful for Modbus, DM drivers, sensors, and long-run serial links. - Dual GbE + optional 10G

Jetson is often the master brain—give it the network plumbing it deserves.

This alone separates a “dev carrier” from a real industrial controller.

2. Vision Interfaces That Match Jetson’s Strength

Jetson lives and dies on camera throughput. So:

- Multiple CSI ports

- Optional GMSL2 mezzanine / header for long-distance automotive-grade cameras

- Dedicated trigger/strobe pins for synced capture

- HDMI/DP for HMI

This makes multi-camera robotics and inspection systems painless.

3. Real Expansion Options

To truly scale:

- PCIe x8 or x16 edge connector

For external NICs, FPGAs, or real-time motion cards. - 2× M.2 Key M (NVMe)

For high-speed logs, AI datasets, and camera bursts. - 1× M.2 Key E/B

For WiFi 6E / 5G modules. - Large GPIO header

With labeled pins for I²C, SPI, I²S, PWM, and general 5V-tolerant I/O.

4. Industrial Power & Safety

A robotics carrier should be ready for cabinet-mount environments:

- 12–48 V DC input (wide range, isolated)

- On-board 24V + 5V accessory rails

- DIN-rail friendly mounting pattern

- Hardware watchdog + power/reset header (PLC-friendly)

- Dual-channel E-STOP input support

- STO (safe-torque-off) compatible output header

These are key when you’re driving servo packs or stepper-FOC drives.

5. Robot-Arm-Friendly I/O

For anyone building articulated systems (like my 6-DOF arm):

- Differential encoder inputs (A/B/Z RS-422)

- Configurable filtering / pullups

- PWM outputs with hardware timers exposed

- High-accuracy timestamp/trigger lines

These save users from bolting on extra encoder breakout boards.

6. Open Software, Not Just JetPack

There’s a big community that wants more flexibility:

- Support for Ubuntu/Debian/Yocto images (not only L4T/JetPack)

- Open schematics + open Device Tree documentation

- Standardized GPIO/SPI/I2C naming

- Straightforward flashing process for non-NVIDIA distros

Jetson hardware is fantastic. Lock-in is not. Look at the Support Forum WOW ![]() the issues are always around the same stumbling blocks. make a list and FIX that!

the issues are always around the same stumbling blocks. make a list and FIX that!

If you make this board easy to adopt in open Linux ecosystems, people will flock to it.

7.  Why This Matters

Why This Matters

This combination turns the carrier into something that can anchor:

- A 6-axis robot arm

- A mobile robot or AGV

- A vision-guided pick-and-place

- A smart industrial controller

- A multi-camera inspection station

- A lab automation platform

- Ability to add a test servo directly connected.

…without adding 3–5 external HATs and adapters.

Just clean, reliable, ready-to-deploy hardware. You guys are NOT sleeping on the Robotics , SO get with it and make us something Unique again. You did it with the “XIAO” ![]()

In Short

and thanks for making it to the end ![]()

If Seeed can integrate:

- Industrial buses (isolated CAN-FD + RS-485)

- Serious camera I/O (CSI + GMSL2 + triggers)

- Real expansion (PCIe, NVMe, M.2)

- Open Linux support

- Robotics-ready I/O (encoders, PWM, safety)

- Proper power & mechanical design

Then the new AGX Orin carrier won’t just match competitors,

it will become the go-to platform for robotics developers and product engineers.

That’s where the real demand is heading and no one has it bagged up.

Add you thoughts but NO laser beam EYEs and Junk…![]()

It would be great to have a Serious Robot arm controller in the Seeed maker space. A targeted Jetson would be Timely IMO. ![]()

Season Greetings ![]()

GL ![]() PJ

PJ ![]()