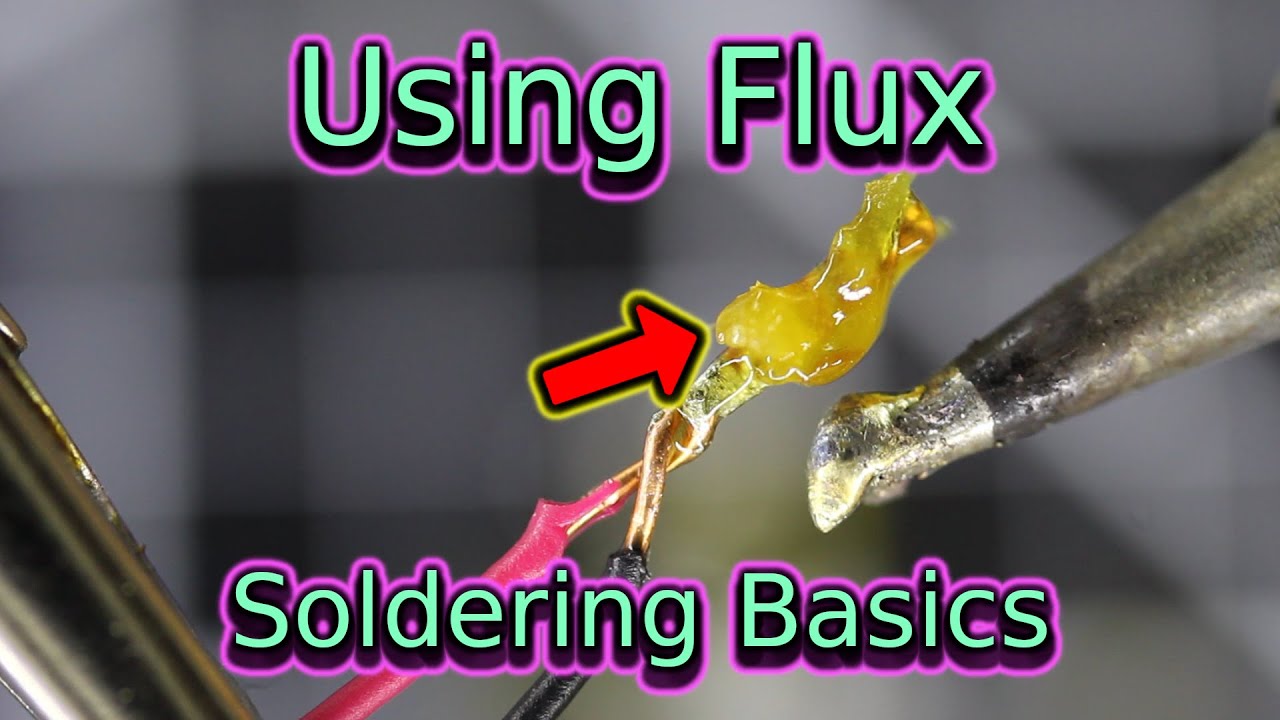

the flux makes the solder flow exactly to the metal.. its like crazy when you try it… the liquid just goes where its supposed to go like it has a mind or something… if you get the paste, it is like paste till you touch the heat and it turns to liquid… it is like a pathway for the solder and it just flows

https://www.amazon.com/Solder-Wire-Rosin-Paste-Flux/dp/B08BLSJHW1

1 Like

oldering is definitely more of an art than just a technical skill, and it can be a bit intimidating when you’re first starting out with custom PCBs or Seeed modules……

I think, the biggest game changer for me was realizing that heat management is everything, you want to heat the pad and the component lead simultaneously for about two seconds before introducing the solder. I used to make the mistake of melting solder directly onto the iron tip, which usually leads to those frustrating ‘cold joints’ that look dull and don’t conduct well… also, never underestimate the power of Flux; it’s the secret to getting those professional, shiny joints even on tiny SMD parts…

If you want a really solid deep-dive into the basics and common mistakes to avoid, I highly recommend checking out the NASA Workmanship Standards for Soldering, it might seem like overkill for hobbyist projects, but the visual examples of ‘good’ vs ‘bad’ joints are incredibly helpful for training your eye. Just remember to keep your tip clean with a brass sponge and take your time; a steady hand comes with practice…

2 Likes

Hi there,

So, Actually it’s the solder mask and the Flux that make it look so nice in the end.

They work together IMO. A good PCB layout and proper mask makes the job easy and clean.

Good video

GL  PJ

PJ