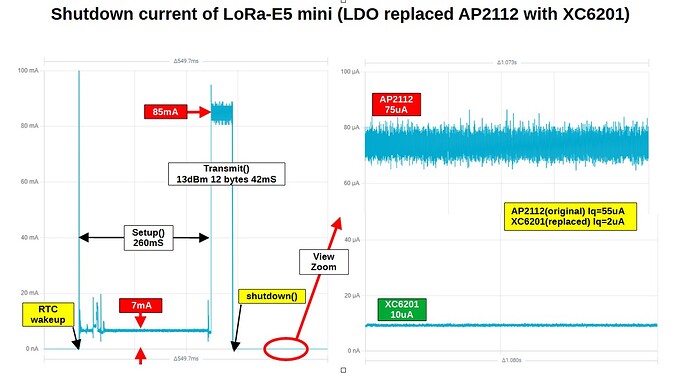

LoRa-E5 mini uses AP2112 as 3.3V LDO, but its quiescent current is relatively large (Iq=55uA) and accounts for most of the 75uA shutdown current. By replacing it with the XC2601, which has a quiescent current as low as Iq=2uA, and by setting unneeded pin as INPUT, the shutdown current can be reduced from 75uA to 10uA. This is expected to have a meaningful effect in battery-powered applications with long shutdown times. I hope this will be of some help to those who are interested.

Please refer to the following link.

‘Programming LoRa-E5 with Arduino, Comparison of LoRa-E5 and LoRa-E5-LE transmit currents’

‘Programming LoRa-E5 with Arduino, Grove-LoRa-E5 sleep current 0.7uA’

3 Likes

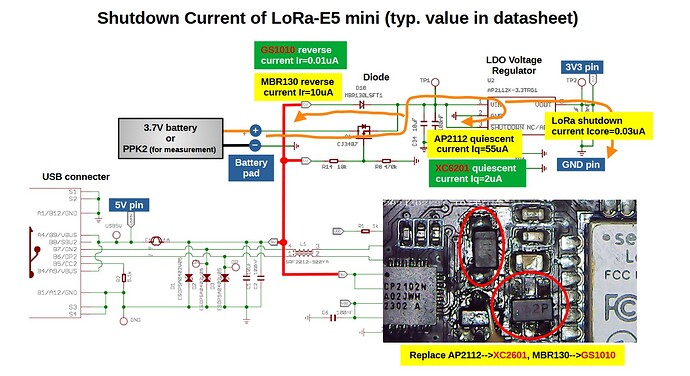

The LoRa-E5-(LE) mini uses an AP2112 3.3V LDO with a high quiescent current of 55uA and a MBR130 Schottky barrier diode with a high reverse current of 10uA. These two components account for most of the 72uA shutdown current. In particular, the reverse current of the diode is very sensitive to temperature; for example, it can easily double when the room temperature changes by 10°C.

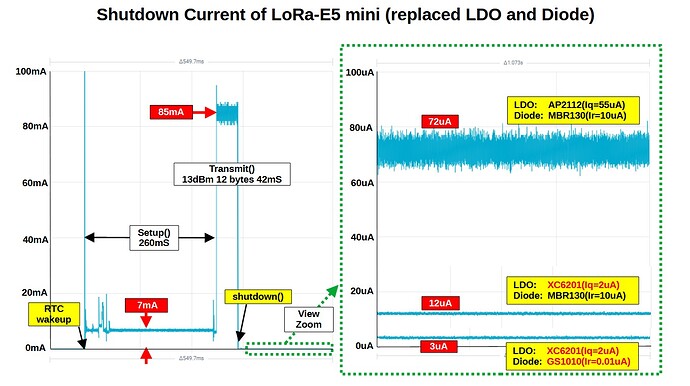

To reduce the shutdown current, the LDOs and diodes were replaced. Considering footprint and availability, I selected the XC2601, an LDO with a small quiescent current of 2uA, and the GS1010, a silicon diode with negligible reverse current. LDOs in particular are 0.9mm pitch surface-mount components, but even I, living in a 2.54mm pitch world, could replace them using an ordinary soldering iron as long as I used a magnifying glass.

As a result, the shutdown current, which was initially 72uA, was greatly improved to 12uA by replacing the LDO, and to 3uA by replacing the diode as well. According to the STM32WLE5JC datasheet, the shutdown current is 31 nA, so the 3 uA shutdown current obtained here seems to be almost the limit value.

The PPK2 was used to measure current and 3.7 V was supplied from the battery pad. Room temperature was kept at 25°C where possible.

Sketch used for the experiment.

STM32WL_TX_ShutdownCurrent.zip (1.6 KB)

2 Likes

TTL 74 series, CMOS 4000 series, uA709, uA741, i8085, MC6800,…

My faverit was 6800 rather than 8085.

As a child, I lived in a vacuum tube world.

Impressive optimization! Lowering the shutdown current from 72uA to 3uA by replacing the LDO and Delete diode is a significant improvement. Your insights and solution will undoubtedly benefit those interested in battery-powered applications. Thanks for sharing this valuable information!

Fantastic optimization! Reducing shutdown current from 72uA to 3uA through LDO replacement and removing 1 diode marks a major enhancement. Your insights will surely aid battery-powered applications. Thanks for sharing!