I have had the power switch on this device break off… It seems the metal can came off and the guts of the switch came out. When this event was observed it was installed inside a sealed container so not sure it recieved any excessive pressure. Seems to be the same switch as the big expansion board. I usually dont use the switch much and just leave it in the on position… SO i dont think it was from excessive use… I wonder if I deserve a replacement?

\I cant tell if this is one of my older units or a newer one… Not sure about the production dates

PS power connector pins are flemsy too… Is a redesign warrented?

PPS what is the future of the embeded power management chip… Are we thinking this is redundent? are we thinking with the fact that most all modern XIAO have onboard battery management we dont need this anymore?

I am thinking that i do not like the clunky solder to the back method… I like to be able to have the charging function AND be able to connect and disconect the unit

This brings the question… should the XIAO battery connector be moved to new pins… especially for new longer-more pins (Pro) units?

Question… could the 5v pin be reconfigured to also be the battery positive pin? what effect would this have if battery and usb are connected at the same time… I would assume as it is currently designed the usb would bypass the charging circuit and overvolt the battery (assume 3.7v) or the battery would backfeed the usb… Any thoughts?

Hi there,

LOL, I broke one on the second one I had, and that was one of my first reply posts , someone was looking for the part number for a PCB. 3-4 years later about 12-15 units or so later, no issues. They should look at Upgrading this and The Xiao Dev_Expansion board.

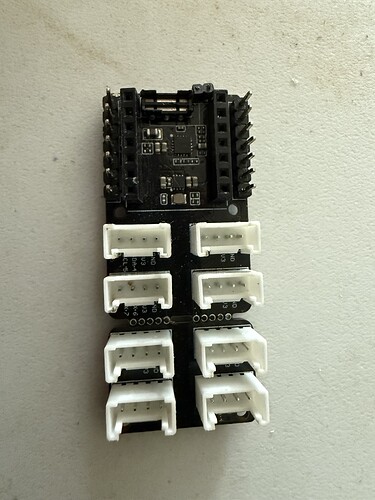

It’s a great Niche device…I’m working on a B2B with Grove Connector for S3 and a PASS-through PCB with IO.

GL  PJ

PJ

Backward compatibility… and COST$

PMIC IC is what the industry is moving to, MAXIM and Nordic offer very good I2C interface IC’s, 1-chip Solutions with full battery management. (works with external battery charger IC’s also) XIAO’s currently only have a battery charger IC, same with the Expansion brd, they are standalone charge Manager IC’s only. it’s why you can’t read the state of charge (SOC) which is the Holy grail for battery management. It is what you need to estimate battery life and power management for your code based on real empirical SOC data for a wareable or truly battery powered device. It’s like trying to walk without legs.

1 Like

The back-soldering method you’re mentioning is less convenient and can be prone to wear or breakage over time. Given that the battery connector and charging circuit are critical components, having a more modular and accessible connection would definitely be an improvement.

Moving the battery connector to pins on the side of the board would improve both convenience and reliability. This way, you wouldn’t need to solder it on the back, and it would allow you to easily connect and disconnect the battery.

1 Like

I think we are rapidly reaching a crossroads with the whole XIAO Ecosystem

It is moving from a Makers Toy to an embeded product.

My problem is i dont think the XIAO needs to be an embeded product, because if you are embeding a product, you can just put the chip right on the circuitboard. XIAO is a Makers Toy… a prototype tool at best, so if what i say is true, the XIAO Ecosystem is orbiting further and further away from its center of mass.

Litterally it is on an eliptical plain, half the time it is close, but more often that not, it is far afield

The bottom side power pads is basicly a need of the embeded surface mounting… which is not maker friendly, along with the castalated pins. It seems more and more, if you want to be a Maker or a toy the better way is to abandon XIAO and go back to generic evaluation boards. They are far more accessable and all the GPIO are lead out