Hello,

I have a PCB board with size 5x10.

Can I order 10 PCB size 10x10 and send you gerber file for 5x10 PCB and you put 2 board of 5x10 on one board 10x10?

Regards

Hello,

I have a PCB board with size 5x10.

Can I order 10 PCB size 10x10 and send you gerber file for 5x10 PCB and you put 2 board of 5x10 on one board 10x10?

Regards

Sorry, we can not do that for you, as the factory will not accept and manufacture that for you as normal.

Hope you can understand.

Regards,

Steve

Hi Steve, I’m assuming that you’re a Seeedstudio staff member since you used “we” in the reply. You answer seems to be not consistent with the answer Liao (also a staff member I think) gave a while ago…

So what is it now? Can I panelize a board (same design) or not??? Seeed really needs to clarify this officially once and for all. Preferably in the Bazaar.

And while you’re at it - please answer my previous question about if your fabhouse does silk clipping or not…

-mats

Hi Mats,

Yes, I’m working for Seeedstudio.

To clarify our fusion pcb service:

Seeed will not do any change for our customer’s gerber files. However, we will do the basic check for these files to judge if they are ok for manufacture, but they are not 100 percent ensured to be ok, as it mainly depend on the validity of the design itself.

The fusion pcb service does not accept the panelized pcb board, except those sever designs seperated by SILK on one pcb , such that you need to cut the board by yourself. Guess that is Liao’s mean.

Hope this can make our fusion pcb service more clear to you guys.

Best Regards,

Steve

Thanks Steve.

In regards to the silk clipping question that is something that the actual PCB manufacturer normally do since they know that no customer ever wants to have silk printed on top of the pads and other exposed copper. They usually remove the silk printing from all parts where there are no soldermask. (This means that they will only print silk on soldermask, nowhere else.)

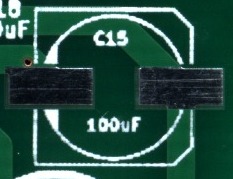

This is an example of where the clipping is performed:

This is when the board house did not clip the silk to the soldermask - causing the pcb to be harder to solder properly.

So what you are saying is that you nor the manufacturer doesn’t do any clipping on the PCBs at all? (The only thing done to the PCBs is that you add the production code on the top silk layer)

I’m not 100% clear on what is allowed or not when it comes to rules of panelizing. It it clear that we will not receive individually cut boards. We have to cut up the received into parts ourselves. That is perfectly fine.

Step & Repeat of a single tiny board: Allowed or not?

Puzzling together several different designs to fit the board size: Allowed or not?

Can each sub-board in the manufactured PCB have a silk (Eagle Layer 21 tPlace) “border” or not if there is an Layer 20 Outline encompassing the entire PCB that is manufactured. Can or not?

So would a file like this ISPtouch_P.zip (30.1 KB) be allowed?

I’m sorry for pestering you with a lot of questions, but I think that a lot of people are interested in the answers - at least I am. ![]()

-mats

Hi Mats,

I guess the silk clipping problem is mainly caused by the designer who does not put the silk properly, as Seeed will not make any changes. The information I got from the fabhouse is that there could be +/-0.15mm error for the silk.

I’m not sure really if I understand what you meant.

For the others questions, see my answers below:

So your ISPtouch_P board could be made without problem.

Regards,

Steve

Thanks Steve,

That was clear and good news

-mats