We did the experiments last month for our own project. Before the production, we hold the pre-meeting at 17:00, we fix the main timeline in the whole schedule. This time, we try to challenge a relatively complex product called Seeeduino Cloud, and we will record all the processes including PCB fabrication.

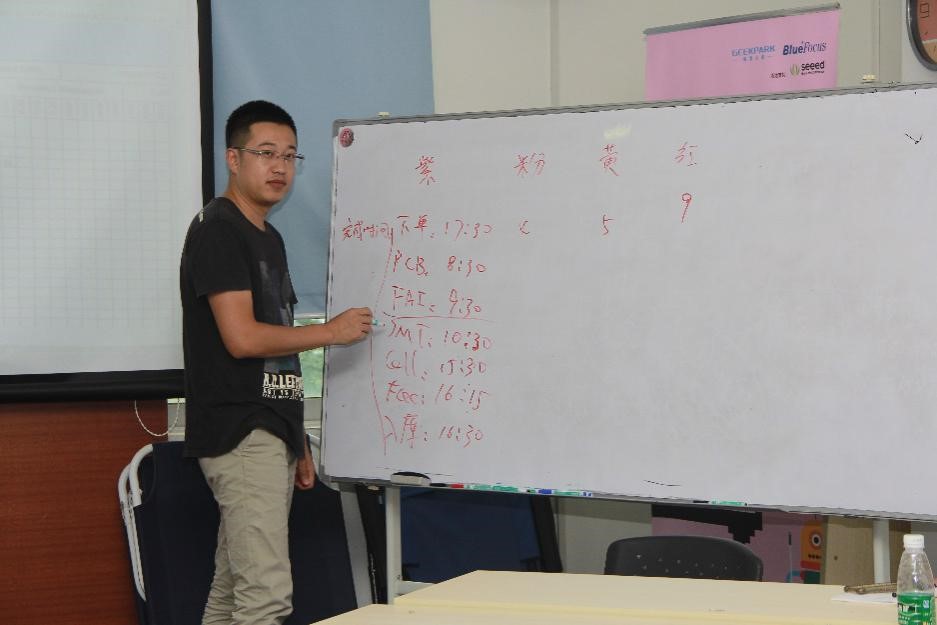

17:00 Pre-meeting

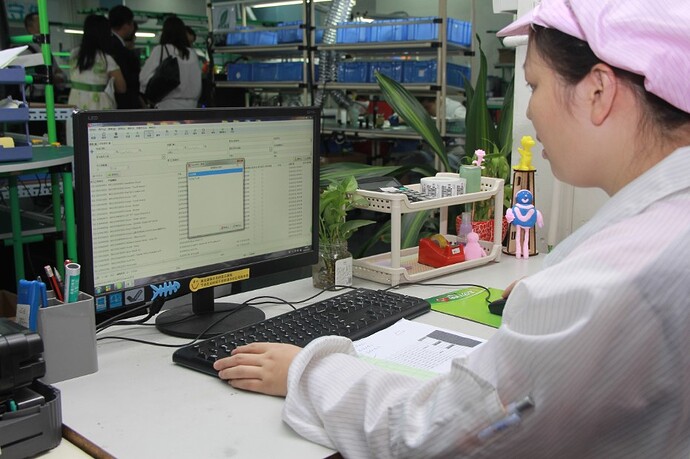

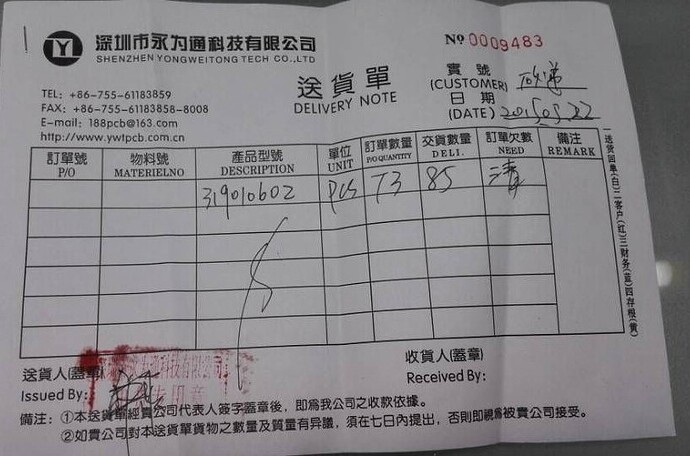

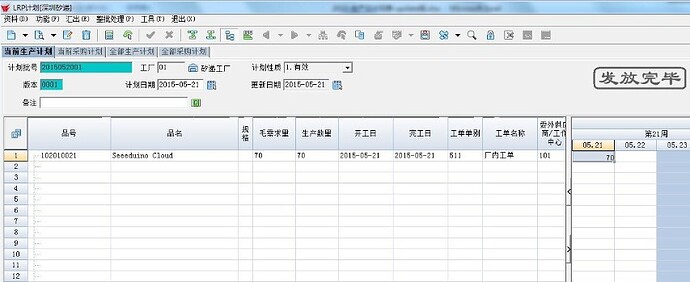

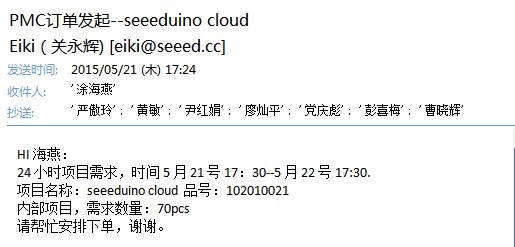

17:30 Release PO to PMC

17: 40 Run MRP

18:00 Preparing components in warehouse

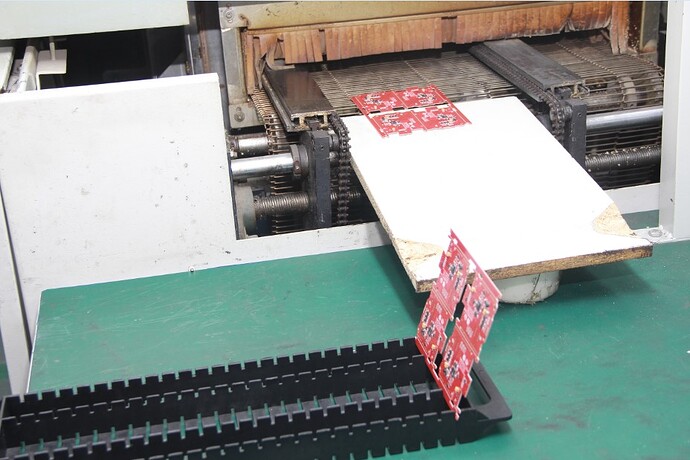

18:30 Our PCB factory Start to produce PCB- Cut Lamination

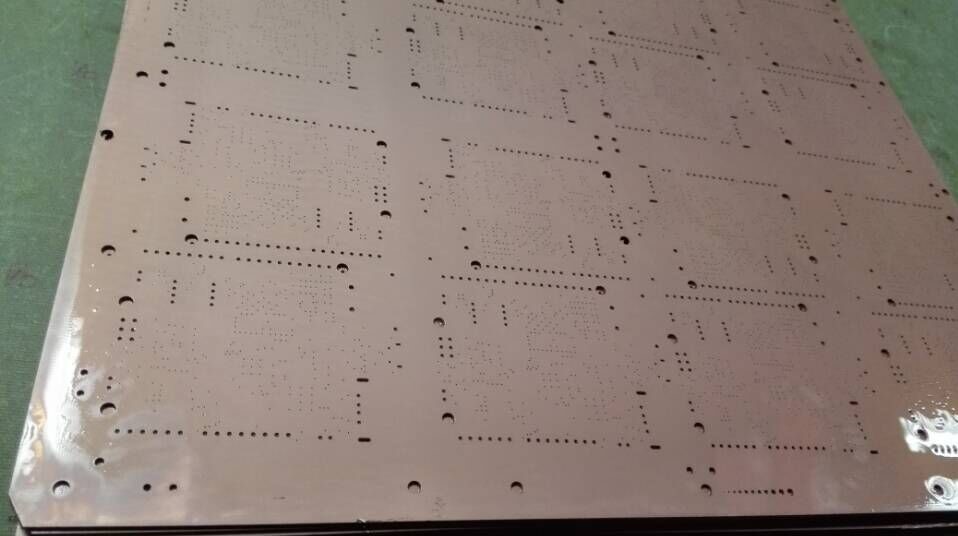

Drilling

Plated through hole

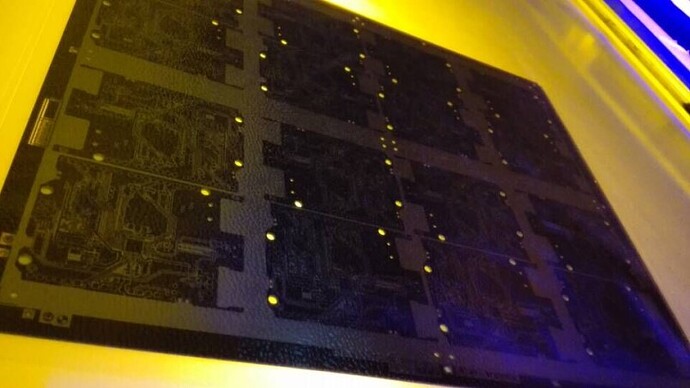

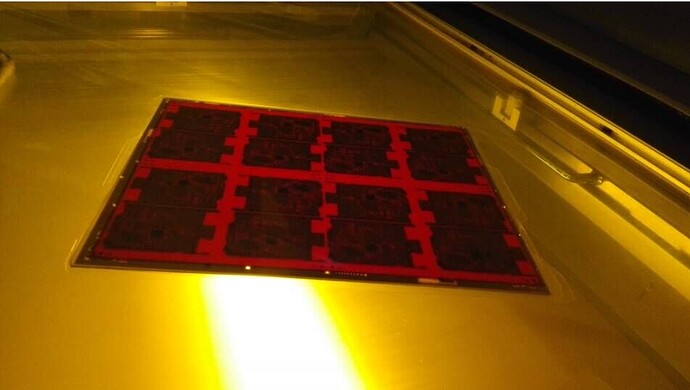

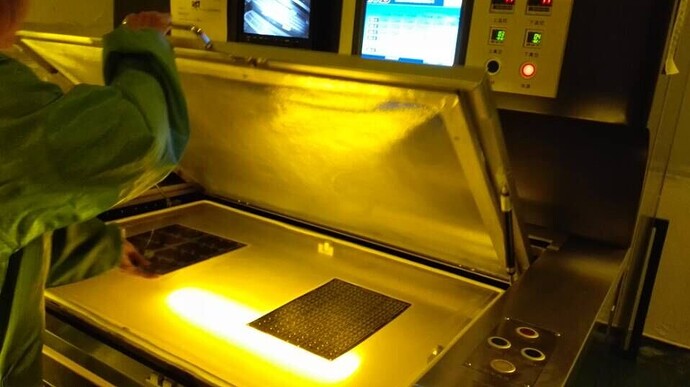

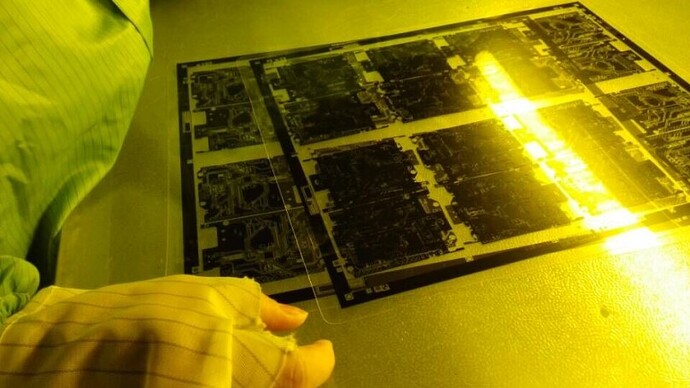

Exposure

Developing

IMMERSION GOLD

Silk screen

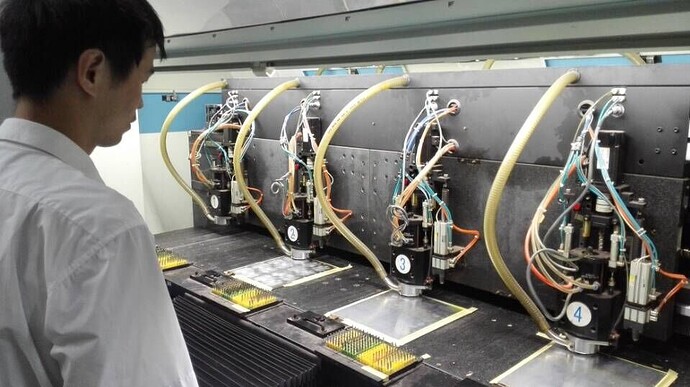

Flying Probe test

Routing

PCB-Packaging

Ready to ship

The next morning~

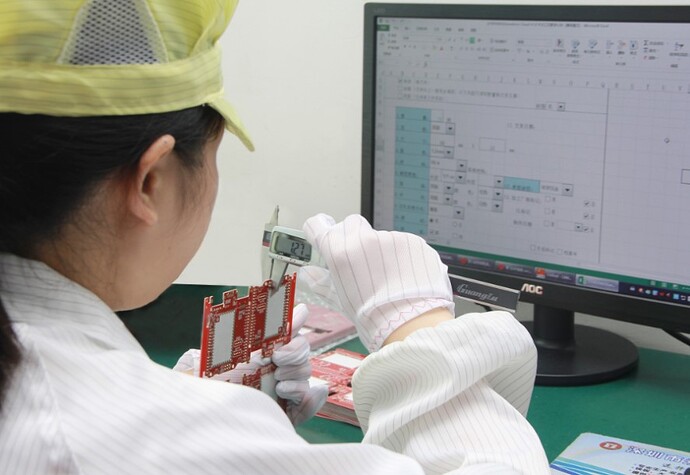

8:30 PCB arrived to our MFG center& Our QC do incoming inspection

8:35 Put electronic components on feeders

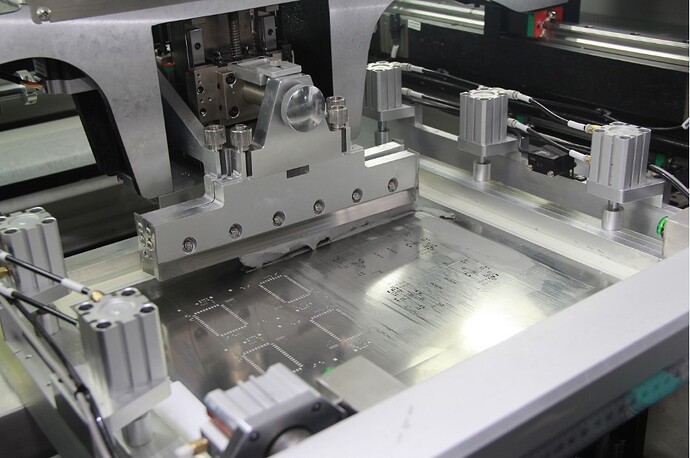

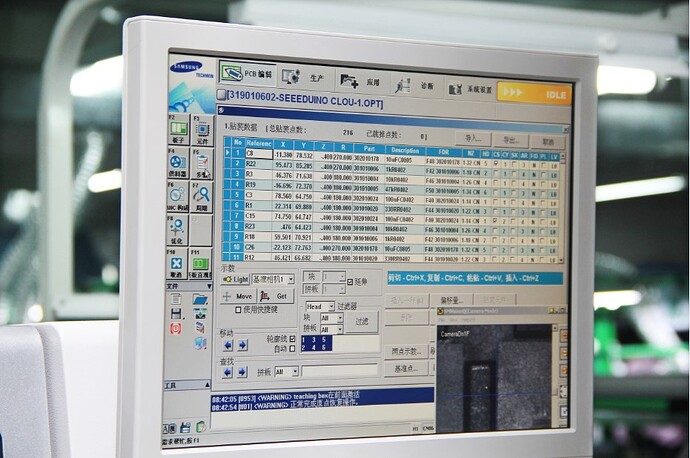

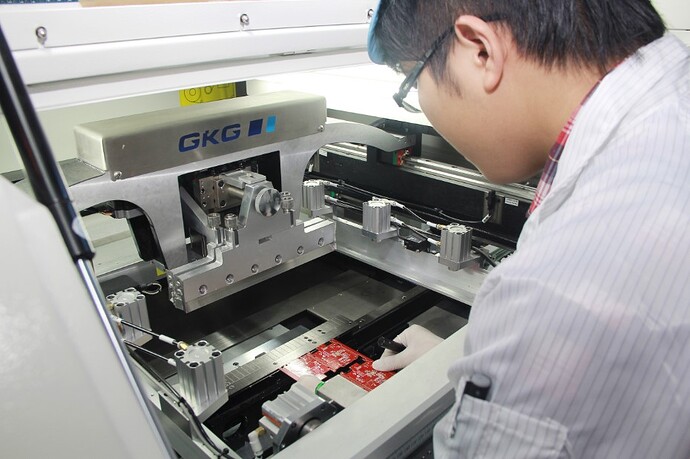

9:00 Debug the Automatic Printer + Pick and place machine

9:10 QC check the components on Pick and place machine.

9:40 Make the first article

10:10 Components inspection

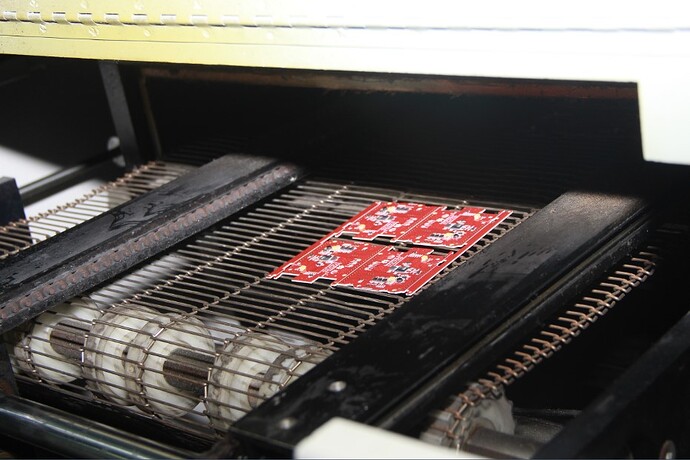

10:20 First article pass reflow

10:30 First article visual inspection

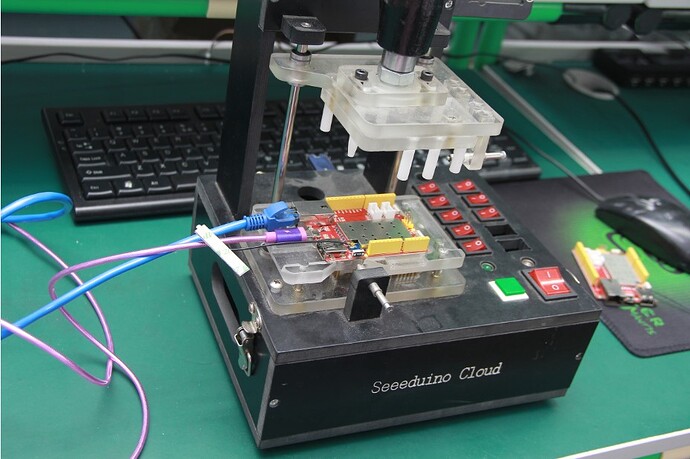

10:40 First article function test

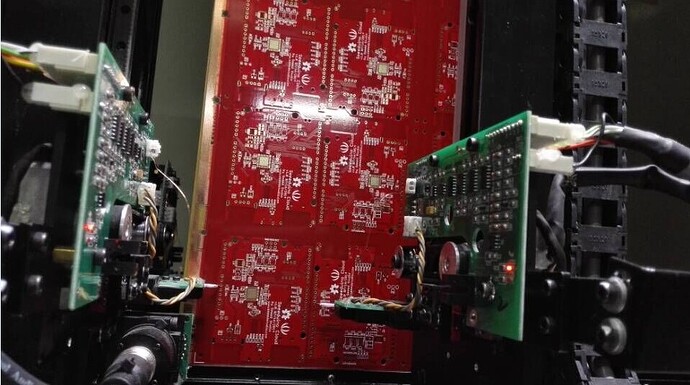

11:00 Start SMT Production

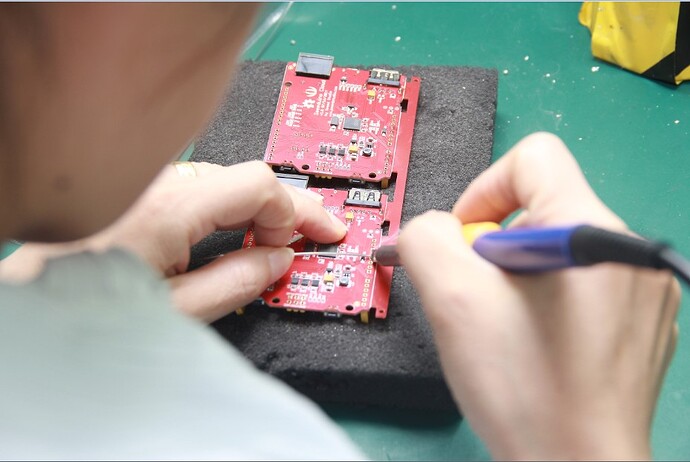

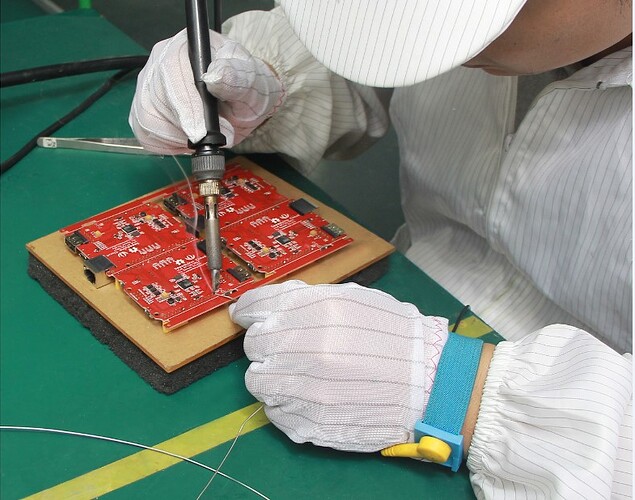

12:00 Start Cell line Production

14:00 Testing

15:00 Failure analysis

15:30 FQC inspection

16:15 Packaging

16:30 Put in storage

In final, we completed the order in 24 hours, thanks all the guys in the team, thanks our project manager Eiki, she not only should ensure all the schedule on the right time, but also need to take all the photoes for sharing. If you want to get more information about 24 hours order service or want to try the service, you can apply it on our propagate page, seeedstudio.com/propagate/app/start, we will do the experiment and share every week.