Hi there,

So Yes, It’s like someone always watching your gear…Motion, Drop, Moisture, Temp. Lock/Unlock BLE , Android & IOS app. to operate.

LOL, yep I started with cardboard rings and magnets , My first 3D printer was a Bday Gift.

I printed the rings from PLA and Later the whole thing in Carbon Fiber, So Strong I can Stand on one (165LBS) on a good day ![]()

Now PCB , Patent and lots of interest… Two Trade Shows NAB and FISH ON!!!

A lot of Hard work, Focus and some vision for the future. Oh’ and a few buck doesn’t hurt Patent attorneys are expensive, Well the good ones anyway!

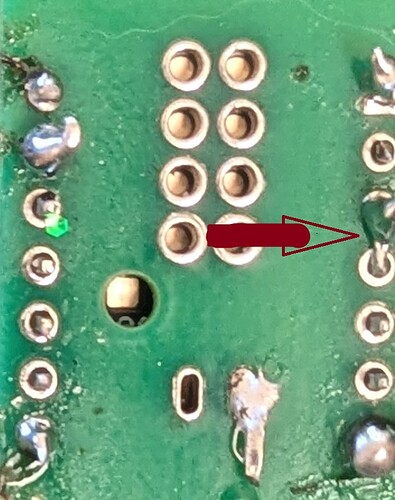

Meanwhile, Tell me the solder bridge in the picture is intensional and also tell me your using a weller 200amp soldering Iron because , Brother that soldering looks Terrible ![]()

So the foot print looks spot on , so there’s That ![]()

The ovals are too small, double check those spaces too. looks wide of the mark.

The plated holes don’t look good either, who made that PCB?

Your Center pads look very good ![]() , Tight! You sure the mounting ears tabs, for the USB-C port are NOT keeping it from sitting perfectly flat and you must be using pins. Ditch that and use the Surface mount Less holes too in PCB it super easy to work with, even if you only have a soldering iron. GET solder PASTE too.with the rolled solder as well.

, Tight! You sure the mounting ears tabs, for the USB-C port are NOT keeping it from sitting perfectly flat and you must be using pins. Ditch that and use the Surface mount Less holes too in PCB it super easy to work with, even if you only have a soldering iron. GET solder PASTE too.with the rolled solder as well.

otherwise increase the size of the "plating " in the hole 1mil to 3 or 4 mm. I wouldn’t waste your time though. do the SMD ![]()

what also you do need the BAT(-) minus as GND look at the pics I posted on the PCB you can see and they are FATTER traces too! USE decoupling caps also and a larger one next to the Xiao’s 3v3 and GND pins.

HTH

GL ![]() PJ

PJ ![]()