Thank you PJ_Glasso

Motor control with the encoder is not the problem. My problem is slow motor response to command because:

- I2C library is too slow (solved with library modification)

- PWM frequency is too slow: 40ms period (not solved)

Here is the context:

We try to find an improve solution for EMG30 motor+encoder+arduino+Arduino motor shield L298.

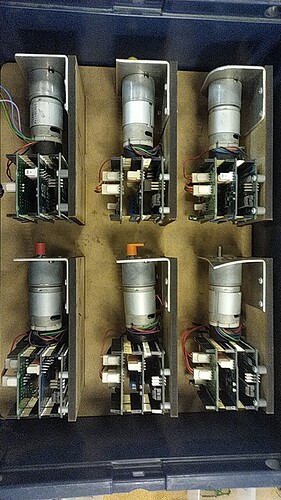

Here is one of the box which we use with our 800 students:

The improved solution (in test) is made with an I2C Motor Driver V1.3

Why migrate: I2C free a lot of port for more complex projets and we can use interrupt pin 2 & 3(pin 3 is used by arduino motor shield).

The old design motor control can be done with this Arduino program (proportional control):

#include <Encoder.h>

Encoder myEnc(2, 5);

long commande = 0;

long Position;

int erreur;

int consigne = 180;

float kp = 20;

void setup() {

pinMode(12, OUTPUT); //pin Direction

pinMode(3, OUTPUT); //pin PWM

}

void loop() {

Position = myEnc.read();

erreur = consigne - Position;

commande = kp * erreur;

moteur(commande);

}

//Commande du moteur

void moteur(int vit) {

if (vit > 255) vit = 255;

if (vit < -255) vit = -255;

analogWrite(3, abs(vit));

digitalWrite(12, (vit > 0));

}

The new design can be control with this program with a library modification:

#include "Grove_I2C_Motor_Driver.h"

#include <Encoder.h>

#define I2C_ADDRESS 0x0f

long consigne = 100;

float kp = 0.8;

Encoder myEnc(2, 3);

void setup() {

Motor.begin(I2C_ADDRESS);

Motor.stop(MOTOR1);

}

void loop() {

long position = -myEnc.read();

long erreur = consigne - position;

float commande = kp * (float)(consigne - position);

float commande2 =constrain(commande,-100,100);

Motor.speed(MOTOR1, commande2);

}

This motor control can only be performed with library modification: remove the delay(4) in the library (point one solved at the beginning of this message). Without this, motor control is impossible

Note that Kp=40 in the old design and Kp= 0.8 in the new design!

The Kp value are obtained with Ziegler–Nichols method

Why such a difference? Because PWM is too slow. The result is very poor performance compared to old design: high error and slow speed: this motor control is not usable in real projects.

Next pictures/text in next message: I cannot post more as new user!